- 您现在的位置:买卖IC网 > Sheet目录343 > MIC4802YME (Micrel Inc)IC WHITE LED DVR 800MA 1CH 8SOIC

Micrel Inc.

Application Information

LED Current

MIC4802

Ultra Fast PWM? Dimming Interface

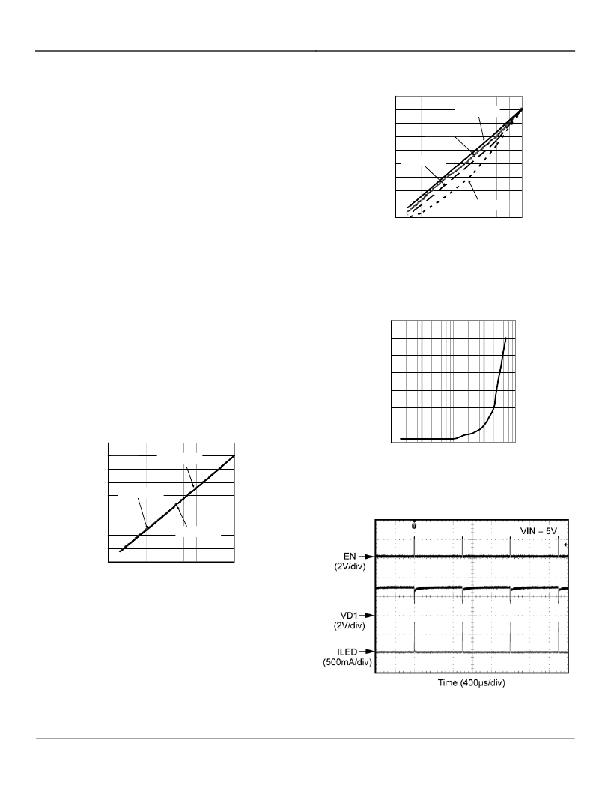

The MIC4802 supports a wide range of PWM control

signal frequencies from 200Hz to 500kHz. This

extremely wide range of control provides ultimate

flexibility for handheld applications using high frequency

PWM control signals.

WLED dimming is achieved by applying a pulse width

modulated (PWM) signal to the END pin. For PWM

frequencies between 200Hz – 10kHz the MIC4802

900

800

700

600

500

400

300

200

vs. PWM Duty Cycle

f PWM = 20kHz

f PWM = 100kHz

f PWM = 200kHz

supports a duty cycle range from 1% to 100%, as shown

in Figure 3. The MIC4802 incorporates an internal

shutdown delay to ensure that the internal control

circuitry remains active during PWM dimming. This

feature prevents the possibility of backlight flickering

100

0

0

20

f PWM = 500kHz

40 60 80

DUTY CYCLE (%)

100

when using low frequency PWM control signals. The

MIC4802 also supports Ultra Fast PWM? frequencies

from 20kHz to 500kHz. Due to input signal propagation

Figure 4. Channel Current Response to PWM Control

Signal Frequencies from 50kHz to 500kHz

delay, PWM frequencies above 20kHz have a non-linear

relationship between the duty cycle and the average

LED current, as shown in Figure 4 and 5. Figures 6

through 9 show the WLED current response when a

PWM signal is applied to the END pin (1) .

35

30

Minimum Duty Cycle

vs. Frequency

(1)

From the low I Q sleep mode higher PWM frequencies above 15kHz

25

require a logic high enable signal for 60 μ s to first enable the MIC4802

prior to PWM dimming .

LED Current

vs. PWM Duty Cycle

900

20

15

10

5

0

800

700

VIN = 5V

f PWM = 1kHz

100

1000 10000 100000

FREQUENCY (Hz)

1000000

600

500

400

300

200

100

0

f PWM = 5kHz

f PWM = 10kHz

Figure 5. Minimum Duty Cycle

for Varying PWM Frequency

0

20

40

60

80

100

DUTY CYCLE (%)

Figure 3. Average Current per LED Dimming

by Changing PWM Duty Cycle for PWM Frequencies

up to 20kHz

Figure 6. PWM Signal at 1% Duty Cycle (I avg = 8mA)

January 2011

8

M9999-013111-B

发布紧急采购,3分钟左右您将得到回复。

相关PDF资料

MIC4807BN

IC DRIVER 80V 8CH ADDRESS 18-DIP

MIC4811YMM

IC WHITE LED DVR HC 6CH 10MSOP

MIC4812YMME

IC WHITE LED DVR HC 6CH 10MSOP

MIC5011YN

IC DRIVER MOSF HI/LOW SIDE 8-DIP

MIC5013YN

IC DRIVER MOSFET HI/LO SIDE 8DIP

MIC5014YN

IC DRIVER MOSFET HI/LO SIDE 8DIP

MIC5016BWM

IC DRIVER MOSF DUAL HI/LO 16SOIC

MIC5018YM4 TR

IC DRIVER MOSFET HI SIDE SOT143

相关代理商/技术参数

MIC4802YME TR

功能描述:LED照明驱动器 800mA Single Channel WLED Driver w/ Ultrafast PWM Control

RoHS:否 制造商:STMicroelectronics 输入电压:11.5 V to 23 V 工作频率: 最大电源电流:1.7 mA 输出电流: 最大工作温度: 安装风格:SMD/SMT 封装 / 箱体:SO-16N

MIC4802YME-TR

功能描述:LED 驱动器 IC 1 输出 线性 PWM 调光 800mA 8-SOIC 制造商:microchip technology 系列:- 包装:剪切带(CT) 零件状态:停产 类型:线性 拓扑:- 内部开关:是 输出数:1 电压 - 供电(最低):3V 电压 -?供电(最高):5.5V 电压 - 输出:- 电流 - 输出/通道:800mA 频率:- 调光:PWM 应用:照明 工作温度:-40°C ~ 125°C (TJ) 安装类型:表面贴装 封装/外壳:8-SOIC(0.154",3.90mm 宽)裸焊盘 供应商器件封装:8-SOIC 标准包装:1

MIC4807

制造商:MICREL 制造商全称:Micrel Semiconductor 功能描述:80V 8-Channel Addressable Low-Side Driver

MIC4807BN

功能描述:IC DRIVER 80V 8CH ADDRESS 18-DIP RoHS:否 类别:集成电路 (IC) >> PMIC - MOSFET,电桥驱动器 - 外部开关 系列:- 标准包装:50 系列:- 配置:高端 输入类型:非反相 延迟时间:200ns 电流 - 峰:250mA 配置数:1 输出数:1 高端电压 - 最大(自引导启动):600V 电源电压:12 V ~ 20 V 工作温度:-40°C ~ 125°C 安装类型:通孔 封装/外壳:8-DIP(0.300",7.62mm) 供应商设备封装:8-DIP 包装:管件 其它名称:*IR2127

MIC4811

制造商:MICREL 制造商全称:Micrel Semiconductor 功能描述:High Current 6 Channel Linear WLED Driver with DAM? and Ultra Fast PWM? Control

MIC4811_1104

制造商:MICREL 制造商全称:Micrel Semiconductor 功能描述:High Current 6 Channel Linear WLED Driver with DAM? and Ultra Fast PWM? Control

MIC4811YMM

功能描述:LED照明驱动器 High Current Six Channel WLED Driver w/ DAM and Ultrafast PWM Control

RoHS:否 制造商:STMicroelectronics 输入电压:11.5 V to 23 V 工作频率: 最大电源电流:1.7 mA 输出电流: 最大工作温度: 安装风格:SMD/SMT 封装 / 箱体:SO-16N

MIC4811YMM TR

功能描述:LED照明驱动器 High Current Six Channel WLED Driver w/ DAM and Ultrafast PWM Control

RoHS:否 制造商:STMicroelectronics 输入电压:11.5 V to 23 V 工作频率: 最大电源电流:1.7 mA 输出电流: 最大工作温度: 安装风格:SMD/SMT 封装 / 箱体:SO-16N